What's New

Products

Dealers

Support

OSHA Seminar

LINK's Links

About LINK

Feedback

OmniLink TSM - Tonnage and Signature Analysis Module

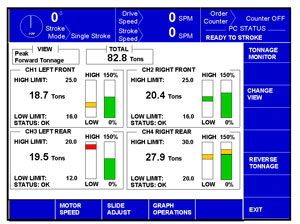

Take a giant step forward in on-line metalstamping process and quality control at a reasonable price. The OmniLink 5000-8A Tonnage Signature Monitor and Analysis Module, TSM, allows the OmniLink 5000 control to monitor and graphically display the force signatures produced in press production Systems.

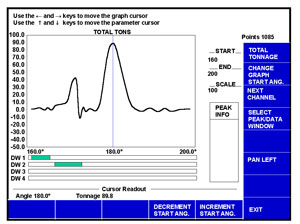

Unlike peak tonnage monitors which can only monitor and display the tooling that punches the highest tonnage during the stroke, the TSM stores up to 4735 samples of the tonnage that occurs throughout the stroke and record the crankshaft angle at which each sample is taken. This ability provides the information necessary to display and therefore analyze and optimize tooling design for the part produced and to pinpoint specific tooling, material, and press problems in the stamping process.

Truly, the OmniLink 5000-8A TSM provides a new dimension in metalstamping process setup and control.

Below are two of the screens for the OmniLink 5000-8A TSM.

Features

Data windows allow monitoring of significant tonnage signature features throughout the stroke

Easy to view tonnage signature displayed graphically on the OmniLink LCD Operator Terminal for each strain link channel

Initial Setpoint limits may be entered manually or automatically determined and set by the TSM after a 16 stroke signature sample.

Stores and recalls high and low setpoint limits and angular position of all data windows used and peak tonnage setpoint limits for up to 105 jobs.

High Setpoint limits can be user programmed to emergency stop or top stop the press

Counters record machine rating alarms and high and low setpoint alarms

Benefits

Provides on-line quality control by monitoring the force signature of every part produced and stopping the press if any variation in the stamping process due to dies, material, or press violates the signature limits established for good parts

Storage and recall of limits and data window crankshaft angles provides paperless record keeping for quick, automatic, consistent, setup to produce good parts each time the die used.

Helps diagnose die, material, or press problems by graphically displaying the force signatures so that signature changes indicate problem areas.

Die makers can use the signature to analyze and optimaize die performance

Helps protect presses from overload or poor load distribution

Protects dies that can withstand one bad hit due to process malfunction

OmniLink TSM Specifications INPUTS: Up to four strain link inputs DISPLAY: The OmniLink Operator Terminal displays all data window and forward and reverse peak tonnages and all signature alarms, and all setpoint limits. The signature screen displays the signature for each channel and total, data window locations, and all setpoint limits. INSTRUMENT ACCURACY: +/- 0.1% of full scale ALARM REPEATABILITY: 0.1 % of full scale MONITORING SPEED: 5 - 800 strokes/minute ALARM RESPONSE TIME: Less than 1.6 milliseconds peak alarm, less than 6.4 millisecond data window alarm MAX NO. OF SAMPLES: 4375 MAX SAMPLE RATE: 200 microseconds per sample MAX ANGULAR RESOLUTION: .022 Degrees